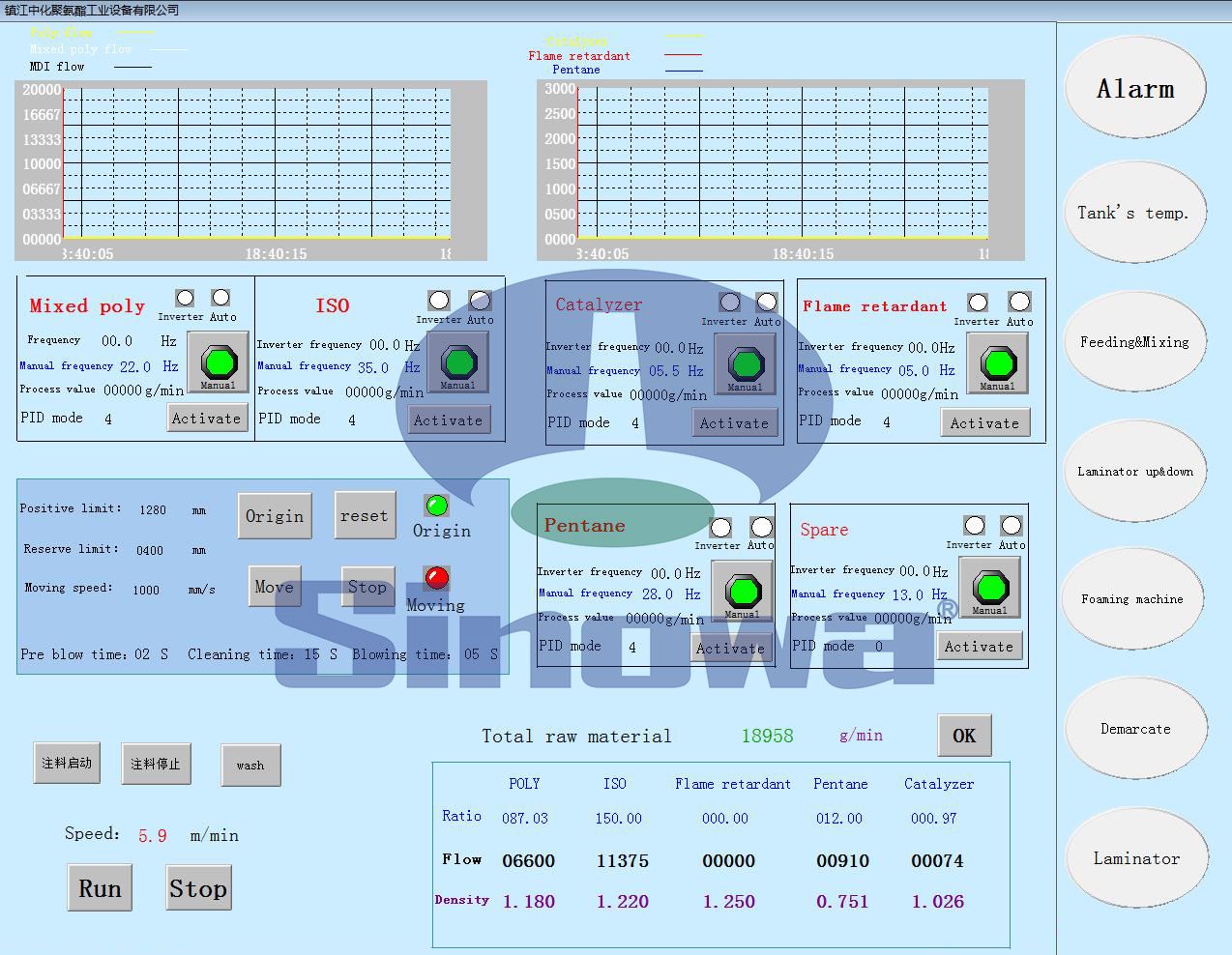

For over ten years, we have established standard technical configuration standards of 2-component 141B foaming system and multicomponent pentane and 141B component foaming system. The online multicomponent foaming technology of our this board production line is based on our strong technical strength, deep understanding of the technological process, rich industrial experience and knowledge and leakage-free pump and valve pipeline configuration technology. We are determined to provide customers with the most economical and reliable multicomponent pentane foaming technology all over the world to meet their pursuit for economic value and environmental protection value.

The online multicomponent pentane foaming system of the production line of the PU laminboard or other types of boards is the innovative and reliable product of Sinowa leading the industry and core representative product based on its technology. With exploration and experience accumulation for several years, the standardization and series of our multicomponent pentane foaming system may provide customers with products with various configurations and help them achieve highest economic and environmental value.

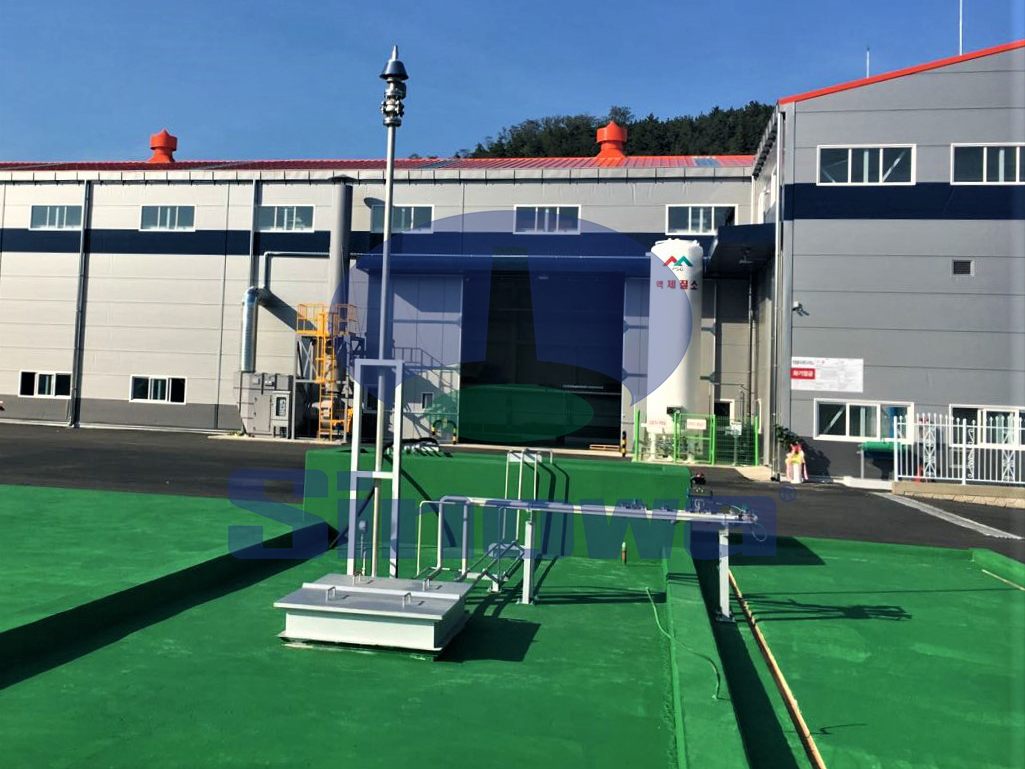

We have detailed schemes from pentane storage to online production and the mature configuration may provide customers with reliable foaming system.

The first-class products are selected for the system from the tank, valve, various pump units to high and low pressure components to ensure that the system accurately and reliably works and has durable and reliable service life and superior life cycle.

The quality of pentane pump units from transportation to accurate measurement and high performance pump units of other components is reputable, complying with the American quality standard API675, which has universal influence all over the world.

For our multicomponent foaming system, priority is given to the safety and reliability; our core technical measures may ensure that the system will not be damaged even if there is operation error or under the extreme operation state. Our built-in safety mechanism may provide customers with protection to the greatest extent.

Based on Sinowa's reliable quality and full service, we have been continuously providing our cos-effective multi-component pentane foaming system to our customers around the world in recent years, accumulating rich experience in overseas production and service.

Sinowa's professional aftersales team ensures that our customer can enjoy our high quality technical services wherever they are on earth.

Sinowa can also design and build advanced standard cyclopentane storage and delivery systems to meet the world's stringent safety and technical standards, so that our customers do not have to worry about building high standard polyurethane sheet production lines.

| FOAMING TYPE | PU | PIR |

|---|---|---|

| FOAMING AGENT | PENTANE OR HCFC-141B | |

| COMPONENT NUM | 2-9 | |

| OUTPUT SCOPE | 30-700g/min | |

| WORKING PRESSURE | 8-20MPa |

|---|---|

| FLOW ACCURACY | 0.5% |

| TEM ACCURACY | ±1℃ |

| WORK METHOD | AUTOMATIC AND MANUAL |

Any enquiry please contact us at your convenience,A prompt response will be done by Sinowa