Potherm® is a premium performance rigid thermoset fiber-free polyisocyanurate insulant adhesively bonded with the facing of kraft paper, cardboard, glass tissue with mineral coating (GTM), glass tissue with bitumen coating (GTB), aluminum foil (F) or multi-layer facing.

The Potherm® has extremely low thermal conductivity values and optimal energy saving performance. especially of the excellent mechanical strength ,exceptional durability and high fire resistance .When exposed to fire, PIR thermal insulation boards form agraphitic protective layer on their surface. It prevents the flame spreading and serves as a reliable protection against further effects of fire. it can almost fulfil all the requirements made of insulation material used in all building or other industry.

Potherm® polyisocyanurate (PIR) foam boards are all manufactured by famous production line which has leading technology performance. The core is a premium performance rigid thermoset fiber-free PIR insulant foamed by self-developed foaming machine, High level of the mixing and creaming technology ensure a leading low fragility and thermal conductivity. The blowing agent has zero Ozone Depletion Potential (ODP) and low Global Warming Potential (GWP).

Rotherm® R1 phenolic foam board is available in thefollowing standard size(s):

| Nominal Dimension | Availability |

|---|---|

| Length (mm) | 2280/3920 |

| Width (mm) | 600 1200 |

| Insulant Thickness (mm) | 12.5 20 30 40 50 60 75 80 90 100 |

| Custom length available | Made to order |

Due to Rotherm® excellent closed cell structure, It hardly absorb water or moisture from the air and surroundings and neither capillary action. Many test results of Rotherm® which indicates that water absorption is usually below 1.5% in volume.

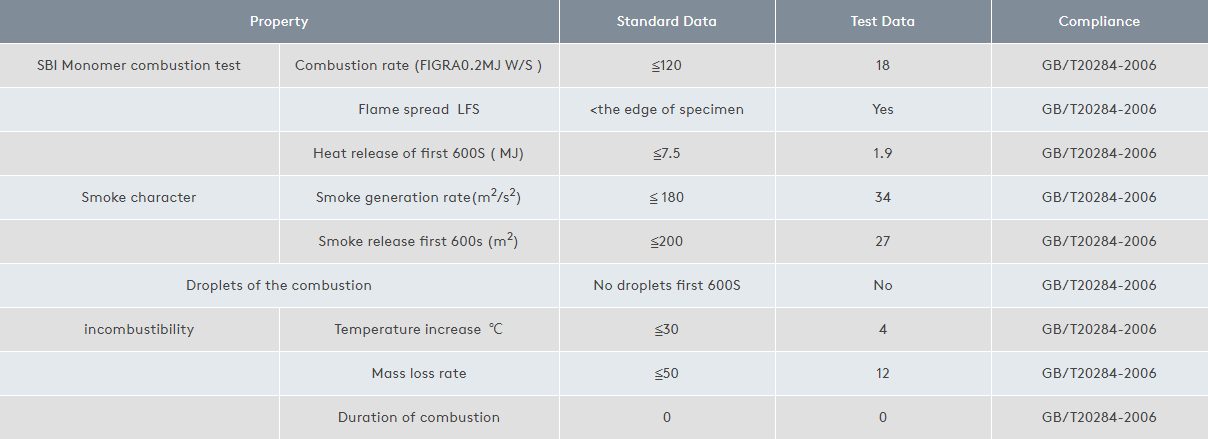

The rigid thermoset insulation core of Rotherm® board has a premium fire resistance performance wich is more suitable for the buildings with structural fire resistance requirements. It is difficult to ignite and it does not transmit fire, difficult to ignite, has no hardly any smoke production and does not produce flaming or non-flaming particles.

SINSU Rotherm® board classified as B according to standard GB/T20284-2006 which has same level specifications as BS EN13501-1.

| Property | Standard data | Test data | Compliance | |

|---|---|---|---|---|

| SBI Monomer combustion test | Combustion rate (FIGRA0.2MJ W/S ) | ≦120 | 18 | GB/T20284-2006 |

| Flame spread LFS | <the edge of specimen | Yes | GB/T20284-2006 | |

| Heat release of first 600S ( MJ) | ≦7.5 | 1.9 | GB/T20284-2006 | |

| Smoke character | Smoke generation rate(m2/s2) | ≦ 180 | 34 | GB/T20284-2006 |

| Smoke release first 600s (m2) | ≦200 | 27 | GB/T20284-2006 | |

| Droplets of the combustion | No droplets first 600S | No | GB/T20284-2006 | |

| incombustibility | Temperature increase ℃ | ≦30 | 4 | GB/T20284-2006 |

| Mass loss rate | ≦50 | 12 | GB/T20284-2006 | |

| Duration of combustion | 0 | 0 | GB/T20284-2006 | |

Depending on its nature excellent chemically neutralcell closed structure and the leading foaming technology , SINSU Potherm® insulation has unexceptionable thermal transfer resistance. Combined with its premium mechanical strength , It is proven to be probably the best thermal insulation material in the construction srctor and many other purpose.

With its excellent compressive stress values combined with elasticity, SINSU Potherm® insulation has proved itself an exceptional thermal insulation material in such pressure-loaded applications over many decades.

SINSU Potherm® is often used in combination with other building materials for large industrial and agricultural buildings. In such applications, it is often exposed to tensile, shear and bending stresses. Base on its stability and exceptional insulation properties,composite elements with SINSU Potherm® insulation has been proven performance record going back decades .

Depending on the density and formula ,The tensile shtrength value of SINSU Potherm® insulation can be up to 900kPa(in accordance with EN 1607) and shear strength maximum value of 450kPa(in accordance with EN 12090),Meanwhile the bending strength value of composite elements with SINSU Potherm® insulation can lie high to 1300 kPa(in accordance with EN 12089 ).

| PROPERTY | TEST DATA | TEST STANDARD |

|---|---|---|

| DENSITY | 42kg/m3 | GB/T6343-2009 |

| Moisture permeability | 1.23×109(m2·s·Pa) | EN 12088 |

| Compressive Strength | 192kPa | EN 1606 |

| Tensile strength | 180kMPa | EN 1607 |

| Shear strength | 290kPa | EN 12090 |

| Thermal conductivity | 0.022w/(m·k) under 25℃ | EN 13165 |

| Dimensional stability | 0.27% under 25℃ 48 hour | GB/T8811-1999 |

| Closed Cell Content | 96.3% | GB/T8811-1999 |

Thanks to its stable natural attributes and high Chemical and biological stability performance,SINSU Potherm® insulation can have an indefinite life if correctly installed.

To ensure safe dimension in many constructions, the maximum deformation of the insulation material must not significantly exceed 0.7% over a load period of 20 and 50 years respectively. Long-term tests on SINSU Potherm® insulation have confirmed reliable compliance with these values.

Premium performance rigid thermoset fiber-free PIR insulant,perfect water and moisture resistance , high mechanical strength , excellent fire performance and stable Chemical and biological stability and variety of facing scheme provide SINSU Potherm® insulation versatility in applications:flat roofing systems with the profiled and concrete foundation; pitched roofs and ceilings;floor insulation system and foot traffic load system; facades system; vertical structural elements, exterior and interior, (walls, partitions, rooms).

Depending on the incomparable thermal and leading comprehensive performance,SINSU Potherm® insulation could be the most effective selection to save energy on buildings and facilities.

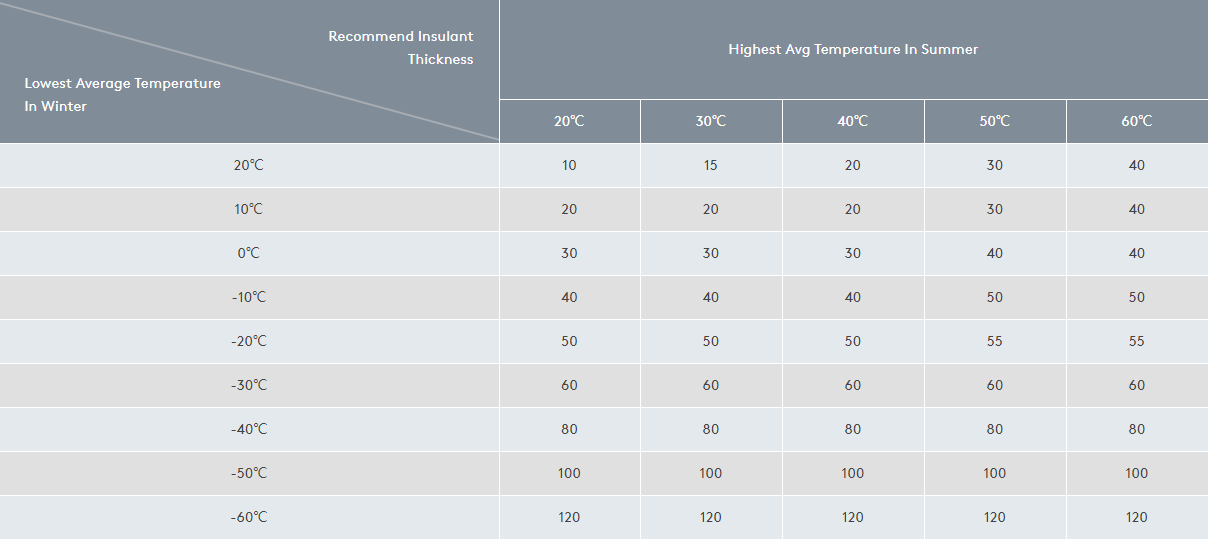

To select a suitable foam board for a high standard building , many conditions need to be considered , where you live , which structure , what’s the thermal level, new or remodeling and even the personal preference...But base on our professional knowledge and experiences , we could offer some essential constructive suggestion such as thickness etc for you warm and great projects .

For thickness,A professional R-value(according to ASTM C518) date sheet could be a important design reference ,Thermal resistance (R–value) varies with thickness and is calculated by dividing the thickness of the board.

| Insulant thckness (mm) | Thermal Resistance (R-value) (m²K/W) |

|---|---|

| 20 (0.79 in) | 0.92 |

| 30 (1.18 in) | 1.38 |

| 40 (1.57 in) | 1.84 |

| 50 (1.97 in) | 2.30 |

| 60 (2.36 in) | 2.76 |

| 70 (2.76 in) | 3.22 |

| 75 (2.95 in) | 3.45 |

| 80 (3.15 in ) | 3.68 |

| 90 (3.54 in) | 4.14 |

| 100 (3.94 in) | 4.60 |

Also you can have a preliminary assessment before the detail calculation from the reference of below recommend sheet, check the building location and start your great beginning.

| Lowest average temperature in winter Recommend insulant thickness |

Highest avg temperature in summer | ||||

|---|---|---|---|---|---|

| 20℃ | 30℃ | 40℃ | 50℃ | 60℃ | |

| 20℃ | 10 | 15 | 20 | 30 | 40 |

| 10℃ | 20 | 20 | 20 | 30 | 40 |

| 0℃ | 30 | 30 | 30 | 40 | 40 |

| -10℃ | 40 | 40 | 40 | 50 | 50 |

| -20℃ | 50 | 50 | 50 | 55 | 55 |

| -30℃ | 60 | 60 | 60 | 60 | 60 |

| -40℃ | 80 | 80 | 80 | 80 | 80 |

| -50℃ | 100 | 100 | 100 | 100 | 100 |

| -60℃ | 120 | 120 | 120 | 120 | 120 |

The R-Value calculation will be used to assess what level of thermal insulation is required to the Building Regulations for both new-builds and refurbishment projects.

The value will depend on a number of different factors including:

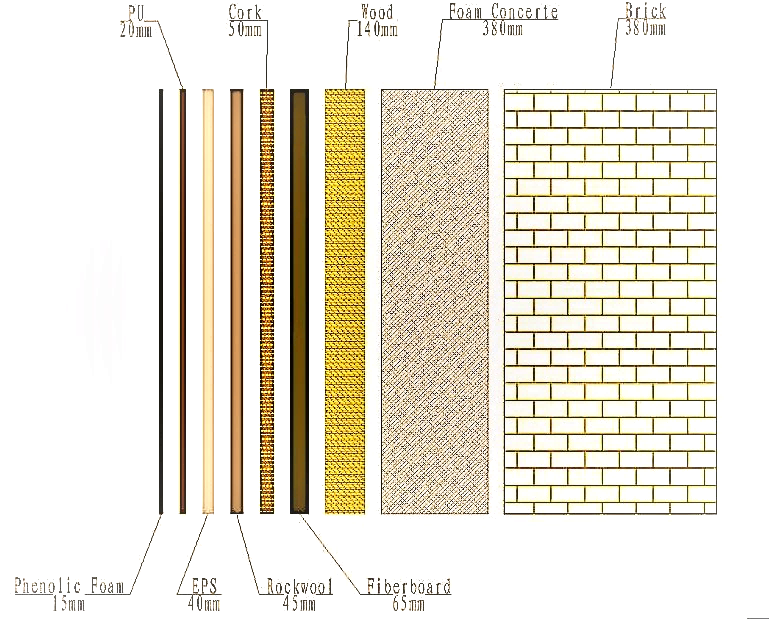

For a refurbishment building, select a same or higher thermal resistance performance SINSU Potherm® insulation to substitute the old products , the below technical sheet may give you some constructive and quick help.

THICKNESS COMPARATION OF DIFFERENT INSULATION MATERIALS FOR THE SAME INSULATION PERFORMANCE

Any enquiry please contact us at your convenience,A prompt response will be done by Sinowa