SINSU Rotherm® is a representative product of high technology and premium quatity . It has several kinds facing adhesively bond with a fiber–free rigid thermoset phenolic insulation core that resists both moisture and water vapor ingress, excellent high thermal insulation performance and naturally premium fire resistance.

Base on the perfect comprehensive performance ,Rotherm® provides a extensive range application of architecture ,ventilation system ,basement ,subway construction , Fireproof and damp & sound insulating material and so on.

Rotherm® R1 phenolic foam boards are all manufactured by advanced production line which has leading technology performance .The core is a premium performance rigid thermoset fiber-free phenolic insulant foamed by self-developed foaming machine , High level of the mixing and creaming technology ensure a leading low fragility and thermal conductivity . The blowing agent has zero Ozone Depletion Potential (ODP) and low Global Warming Potential (GWP).

Rotherm® R1 phenolic foam board can have an indefinite life if If correctly installed。Its durability depends on the supporting structure and the conditions of its use.

| Property | Rotherm® R1 phenolic foam board |

Rotherm® R2 silicon based phenolic foam board |

|---|---|---|

| R-value (1.97 in) | 28.3 on 50mm (ft2·k/w) | 20.7 on 50mm (ft2·k/w) |

| Normal thickness | 20;30;40;50;60;75;80;90;100(mm) 0.79;1.18;1.57;1.97;2.36;2.95;3.15;3.54;3.93(in) |

|

| Standard dimensions Length(mm/in) Width(mm/in) |

2400/3960 (mm)94.488/155.905 (in) 600/1200 (mm)23.622/47.244 (in) |

|

| Density (kg/m3) | 35 | 70 |

| Compressive strength (psi) |

21.7 | 33.88 |

| Tensile strength (psi) |

23.2 | 17.24 |

| Closed Cell Content (% of cells closed) |

95.7 | 94 |

| Air Permeance (L/S/m 2 ) / (cfm/ft 2 ) |

0.001/0.000 | 0.001/0.000 |

| Water Absorption, Max. (% by volume) |

1.02 | 1.19 |

| WaterVapor Permeance, Max. (perm) |

0.43 | 0.56 |

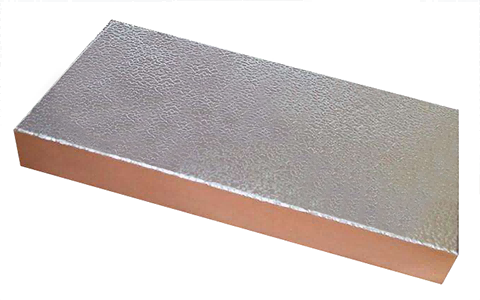

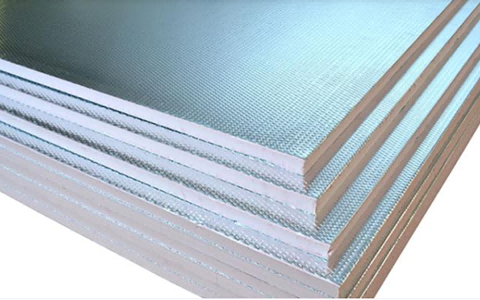

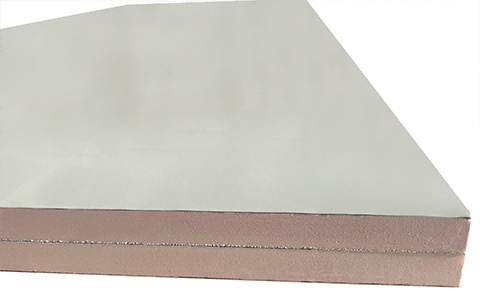

Rotherm® R1 phenolic foam board is a premium performance insulation product, with a fiber–free rigid thermoset phenolic core, faced on both sides with a low emissivity composite foil facing like a glass tissue ,grid aluminum foil ,common aluminum foil ,cement cloth and bare surfaces.

Rotherm® R1 phenolic foam boards are all manufactured by advanced® production line which has leading technology performance .The core is a premium performance rigid thermoset fiber-free phenolic insulant foamed by self-developed foaming machine , High level of the mixing and creaming technology ensure a leading low fragility and thermal conductivity . The blowing agent has zero Ozone Depletion Potential (ODP) and low Global Warming Potential (GWP).

Rotherm® R1 phenolic foam board is available in thefollowing standard size(s):

| Nominal Dimension | Availability |

|---|---|

| Length | 2400/3960 |

| Width | 600 1200 |

| Insulant Thickness | 20 30 40 50 60 75 80 90 100 |

| Custom length available | Made to order |

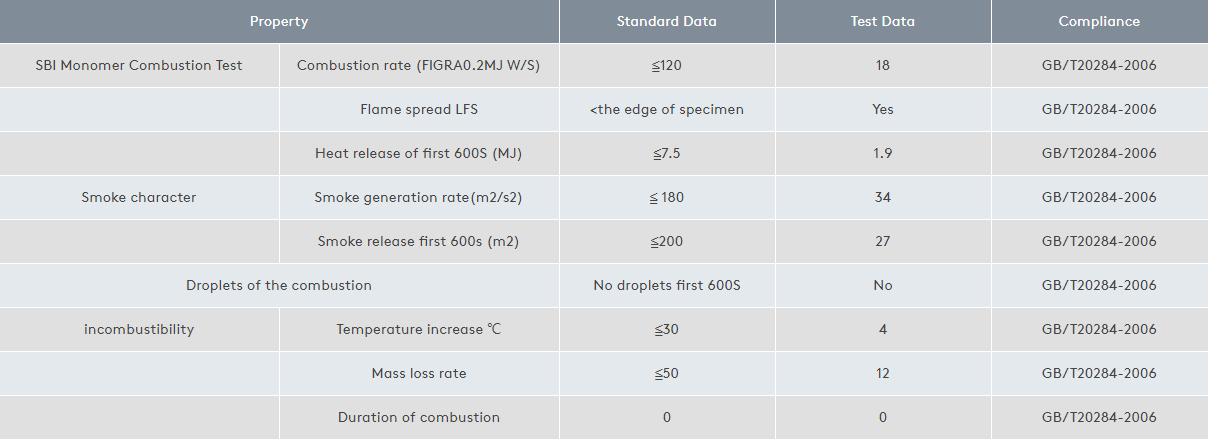

Properly applied phenolic insulation foam, according to the EPFA,the fire performance of Rotherm® R1 phenolic foam board meets or exceeds international building insulation and fire regulations,low flame ,Negligible smoke developed and No dropping, no melting under high temperature but carbonized.reaction to fire.

| Property | Standard data | Test data | Compliance | |

|---|---|---|---|---|

| SBI Monomer Combustion Test | Combustion rate (FIGRA0.2MJ W/S) | ≦120 | 18 | GB/T20284-2006 |

| Flame spread LFS | <the edge of specimen | Yes | GB/T20284-2006 | |

| Heat release of first 600S (MJ) | ≦7.5 | 1.9 | GB/T20284-2006 | |

| Smoke character | Smoke generation rate(m2/s2) | ≦ 180 | 34 | GB/T20284-2006 |

| Smoke release first 600s (m2) | ≦200 | 27 | GB/T20284-2006 | |

| Droplets of the combustion | No droplets first 600S | No | GB/T20284-2006 | |

| incombustibility | Temperature increase ℃ | ≦30 | 4 | GB/T20284-2006 |

| Mass loss rate | ≦50 | 12 | GB/T20284-2006 | |

| Duration of combustion | 0 | 0 | GB/T20284-2006 | |

Rotherm® R1 phenolic foam board has perfect water and moisture resistance performance ,fiber -free structure ensures no moisture build up occurs to compromise the system by limiting water accumulation to the puncture area only. Low water vapor seepage makes this insulationfoam low in water absorption.

Base on the advanced production line and foaming technology,Rotherm® R1 phenolic foam board own leading insulation performance and more better brittleness index . Through continuous innovation and research , our Rotherm® R1 phenolic foam board thermal conductivity is even as low as 0.019 and the more lower index products are also under the development.. In the meantime ,depends on the premium mixing and creaming technology , the brittleness of the Rotherm® R1 phenolic foam board is greatly reduced.

Rotherm® R1 phenolic foam board can have an indefinite life if If correctly installed.Its durability depends on the supporting structure and the conditions of its use.

Resistance to Solvents, Fungi.

The insulation core of our Rotherm® R1 phenolic foam board s has resistant performance to short–term contact with petroleum and with most dilute acids, alkalis and mineral oils. But at meanwhile it is not resistant to some solvent–based adhesive systems,particularly those containing methyl ethyl ketone. Therefore, the damaged boards or boards that have been in contact with harsh solvents or acids and the Adhesives containing such solvents should not be selected.

| PROPERTY | TEST DATA | TEST STANDARD |

|---|---|---|

| DENSITY | 55kg/m3 | GB/T6343-2009 |

| Moisture permeability | 1.23×109(m2·s·Pa) | GB/T17146-1997 |

| Compressive Strength | 0.19MPa | GB/T8813-2008 |

| Tensile strength | 0.18MPa | GB/T1040-2006 |

| Thermal conductivity | 0.028w/(m·k) under 25℃ | GB/T10294-2008 |

| Dimensional stability | 0.12% under 7025℃ 48 hour | GB/T8811-1999 |

| Closed Cell Content | 96% | GB/T8811-1999 |

| Thermal resistance | 0.88m2·k/w | GB/T10295-2008 |

| PH value | 6.4 | GB/T14074.4-1993 |

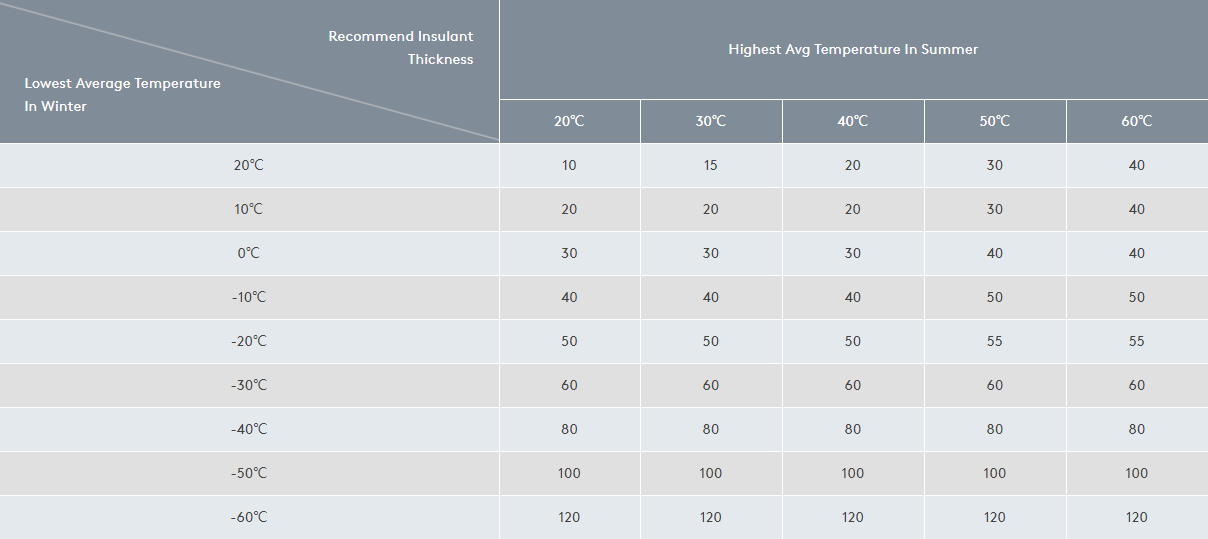

To select a suitable foam board for a high standard building , many conditions need to be considered , where you live , which structure , what’s the thermal level, new or remodeling and even the personal preference...But base on our professional knowledge and experiences , we could offer some essential constructive suggestion such as thickness etc for you warm and great projects .

For thickness,A professional R-value(according to ASTM C518) date sheet could be a important design reference ,Thermal resistance (R–value) varies with thickness and is calculated by dividing the thickness of the board.

| Insulant thckness (mm) | Thermal Resistance (R-value) |

|---|---|

| 20 (0.79 in) | 7.1 |

| 30 (1.18 in) | 10.5 |

| 40 (1.57 in) | 13.9 |

| 50 (1.97 in) | 17.4 |

| 60 (2.36 in) | 20.9 |

| 70 (2.76 in) | 24.4 |

| 75 (2.95 in) | 26.3 |

| 80 (3.15 in ) | 27.5 |

| 90 (3.54 in) | 31.8 |

| 100 (3.94 in) | 35.3 |

Also you can have a preliminary assessment before the detail calculation from the reference of below recommend sheet, check the building location and start your great beginning.

| Lowest average temperature in winter Recommend insulant thickness |

Highest avg temperature in summer | ||||

|---|---|---|---|---|---|

| 20℃ | 30℃ | 40℃ | 50℃ | 60℃ | |

| 20℃ | 10 | 15 | 20 | 30 | 40 |

| 10℃ | 20 | 20 | 20 | 30 | 40 |

| 0℃ | 30 | 30 | 30 | 40 | 40 |

| -10℃ | 40 | 40 | 40 | 50 | 50 |

| -20℃ | 50 | 50 | 50 | 55 | 55 |

| -30℃ | 60 | 60 | 60 | 60 | 60 |

| -40℃ | 80 | 80 | 80 | 80 | 80 |

| -50℃ | 100 | 100 | 100 | 100 | 100 |

| -60℃ | 120 | 120 | 120 | 120 | 120 |

For a remodeling building, select a same and highermal resistance performance Rotherm® R1 foam board to substitute the old products , the below technical sheet may give you some constructive and quick help.

THICKNESS COMPARATION OF DIFFERENT INSULATION MATERIALS FOR THE SAME INSULATION PERFORMANCE

Any enquiry please contact us at your convenience,A prompt response will be done by Sinowa